Process solutions

centrotherm has been developing and implementing innovative thermal solutions for more than 70 years. As a leading and globally operating technology group, we offer production solutions for the semiconductor and microelectronics industries.

The continuous further development of our technology for thermal processing and layer deposition on semiconductor materials is the basis for successful partnerships with industry and science. Our customers worldwide appreciate the process stability, scalability and reliability of our production systems in laboratory or pilot scale as well as in mass production. We develop pioneering process technologies that are specifically tailored to our customers' requirements. In this way, we generate competitive advantages for our customers through dedicated innovative process and production solutions.

Our process expertise

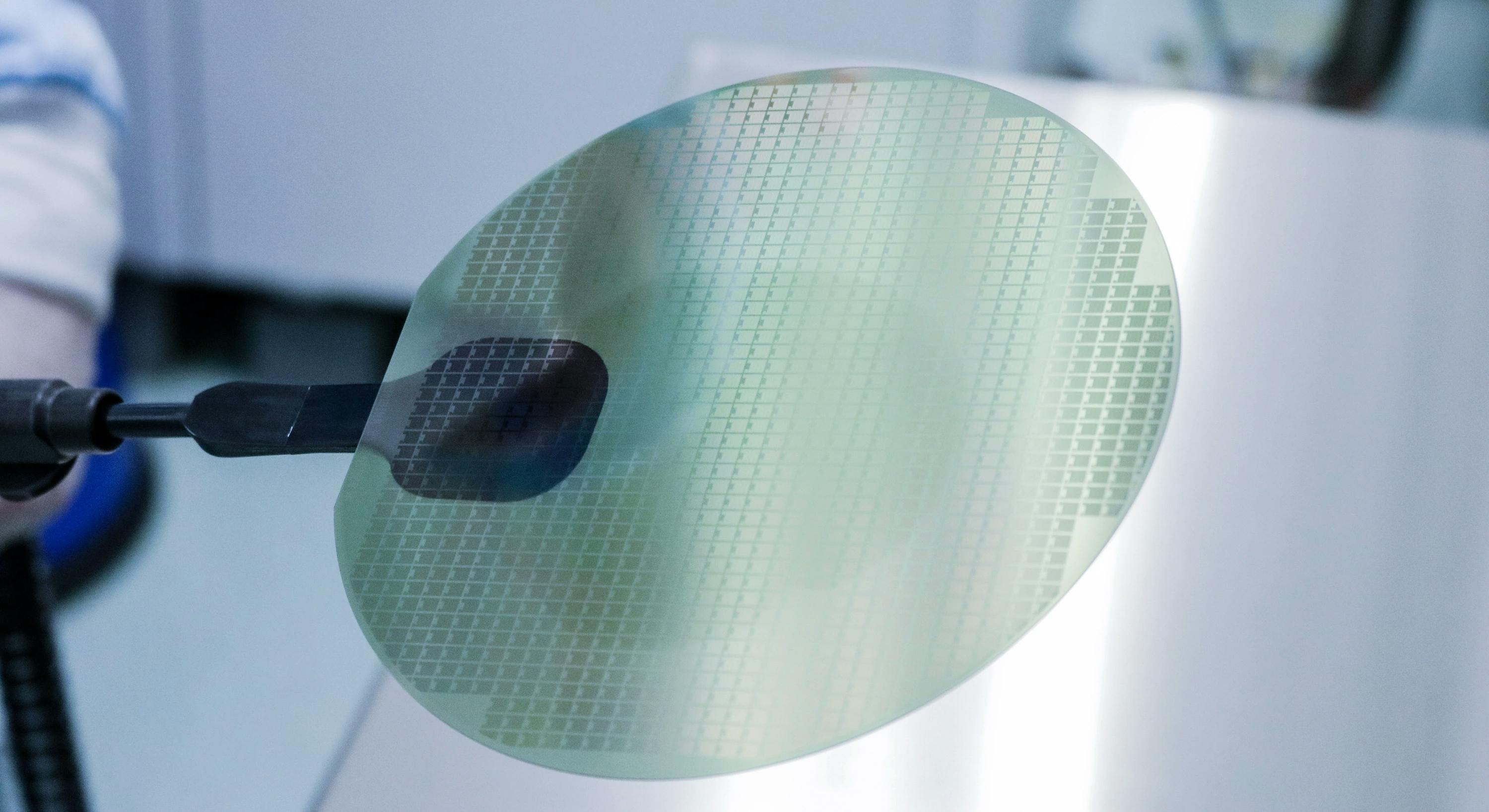

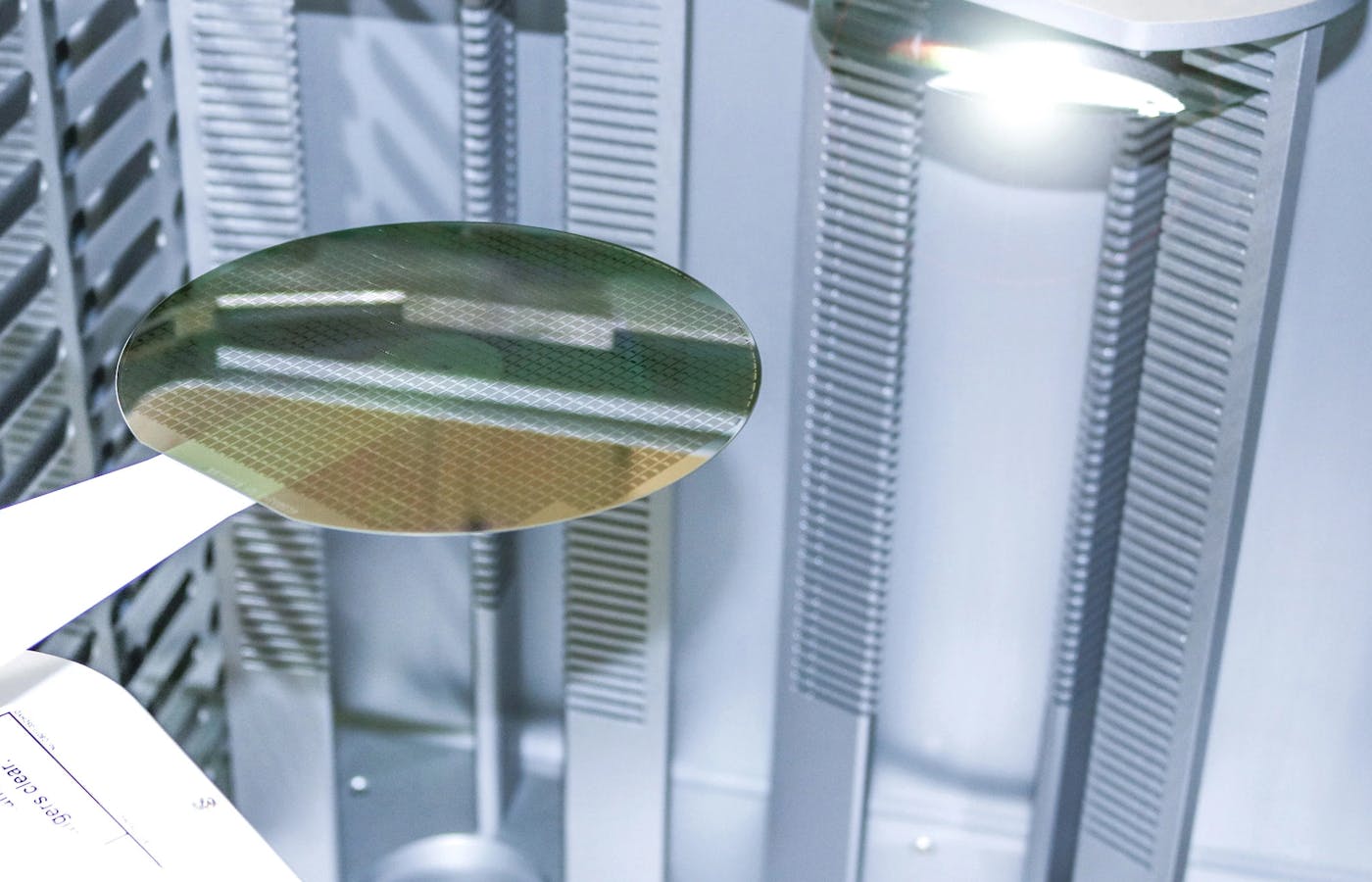

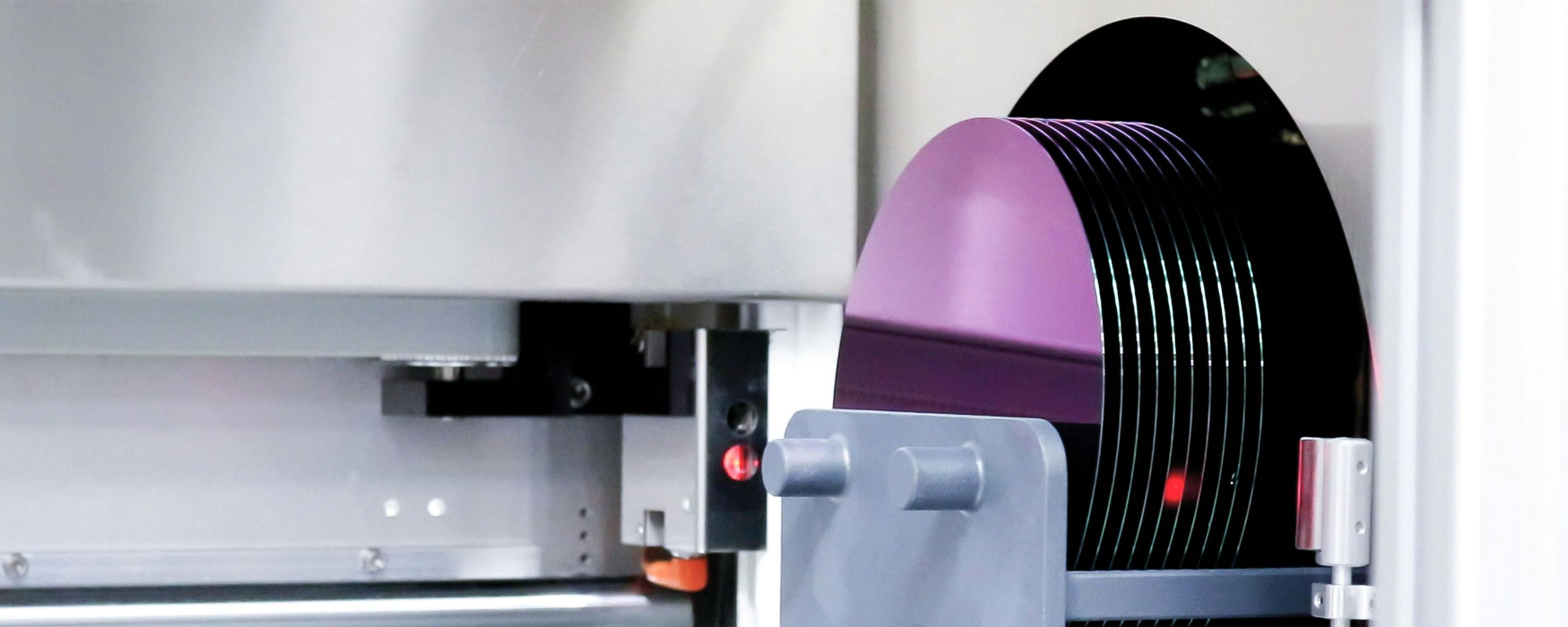

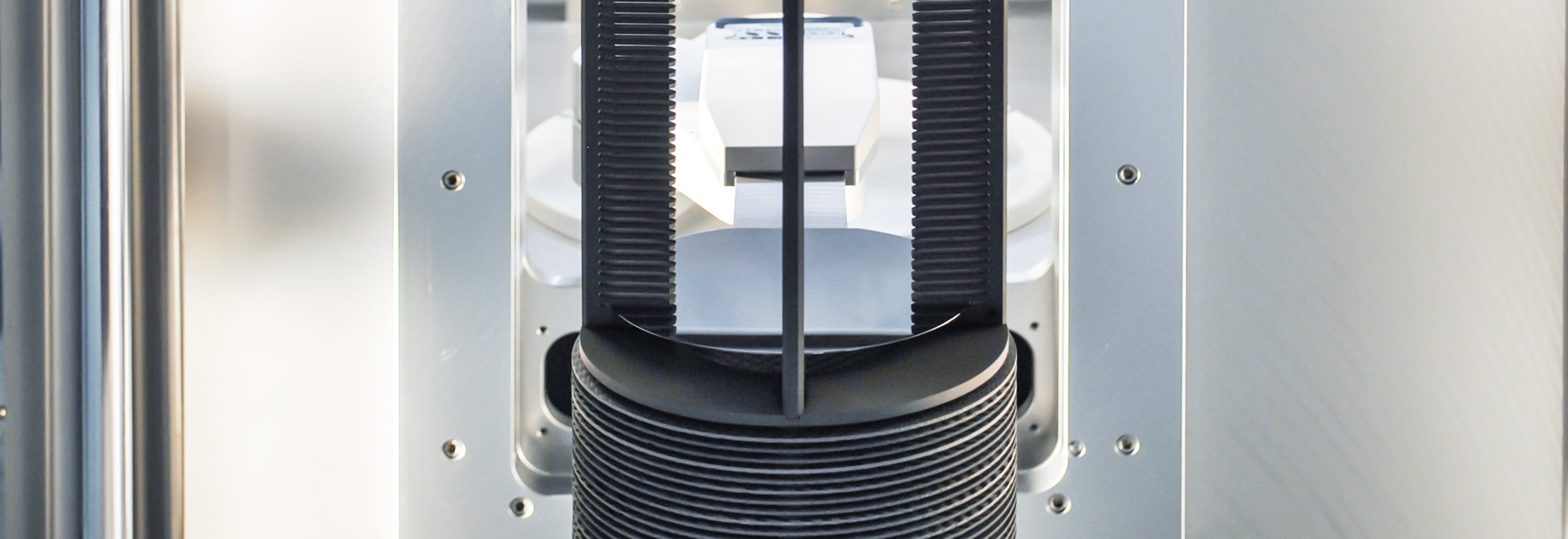

Wafer manufacturing

Silicon

- Annealing

- Wet / dry oxidation

- LP Poly

SOI

- Wet / dry oxidation

SiC

- HT Annealing

Power semiconductor

MOS

- Diffusion / Oxidation

- LPCVD

- RTP

IGBT

- HT Oxidation / Drive-in

- Al/Ga Deposition / Diffusion

- Thin-wafer annealing

- Vacuum soldering

GaN HEMT

- Dielectrics / Passivation

- RTP

SiC MOSFET

- Annealing (Activation / Trench smoothing)

- Oxidation (Gate /POA)

- RTP

MEMS / TSV

- Poly Si / SiGe (doped / undoped)

- Low-stress SiN / SiO

- Doped / undoped SiO2 (TEOS / LTO / HTO)

- Vacuum soldering

Optoelectronics

VCSEL

- LT wet oxidation

- Vacuum soldering

Laser diodes / Fiber optic communication

- Vacuum soldering

Advanced Packaging

- Vacuum soldering

- Bump reflow

- Vacuum sealing

Passive components

Copper

- Direct Copper Bonding (DCB)

- Active metal brazing

Ceramics

- Sintering (MLCC / LTCC)

Glass

- Reflow soldering

- Glass to substrate bonding