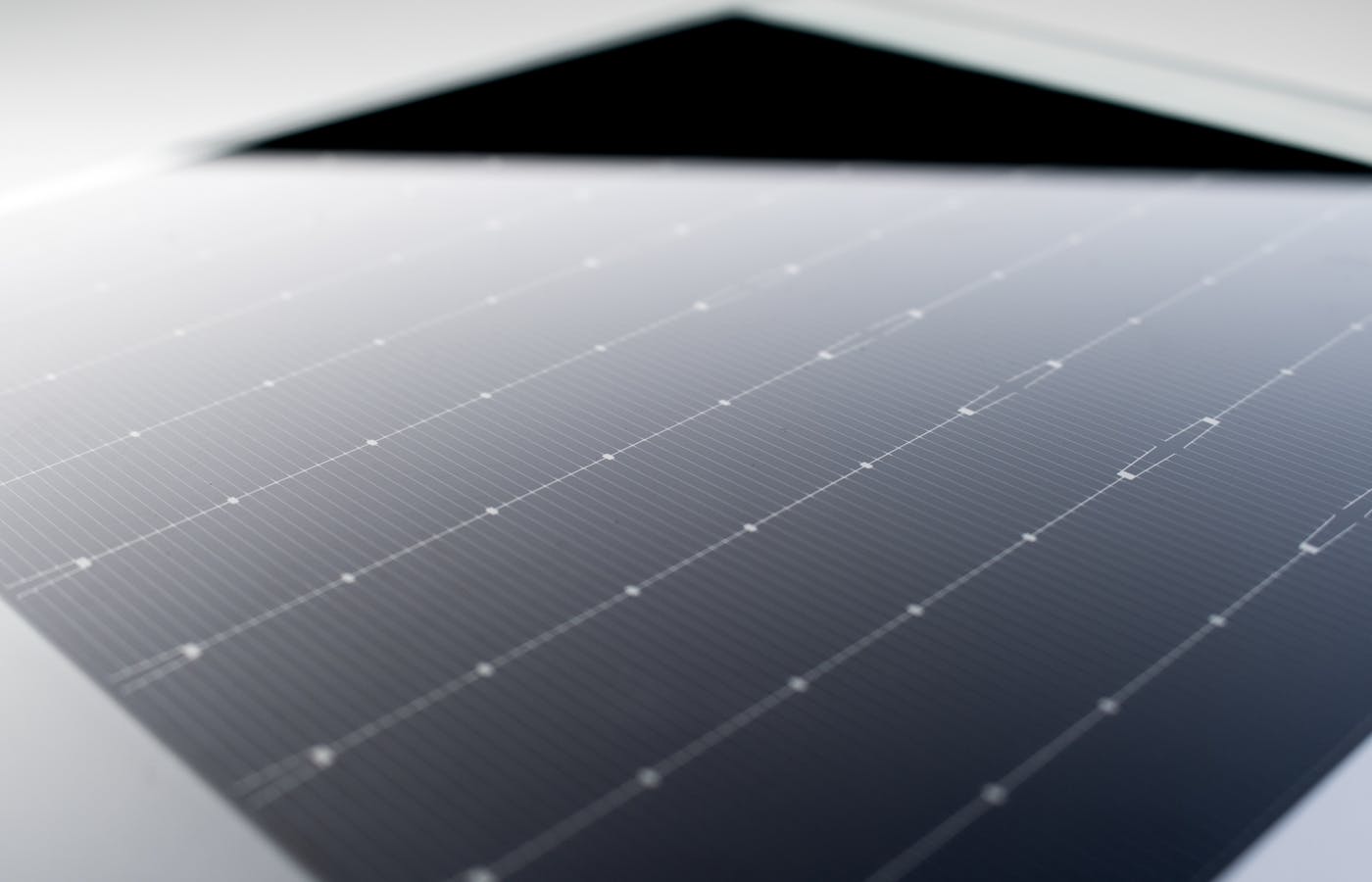

Production solutions

for high-efficiency solar cells

As one of the pioneers of the photovoltaics industry, centrotherm has established itself as a strong partner for renowned solar cell manufacturers with more than 40 years of experience.

We have installed over 50 turnkey production lines and more than 3500 individual process systems at our customers' sites worldwide. Our production lines have proven themselves in terms of availability and process stability in the demanding mass production of solar cells.

0

Turnkey lines

0

PECVD systems

0

Diffusion furnaces

0

Fast firing furnaces

Helge Haverkamp, CTO„In order to develop the ideal process technology for current and upcoming cell technologies we cooperate closely with our customers and research institutes.“