Our Mission

Welcome to centrotherm

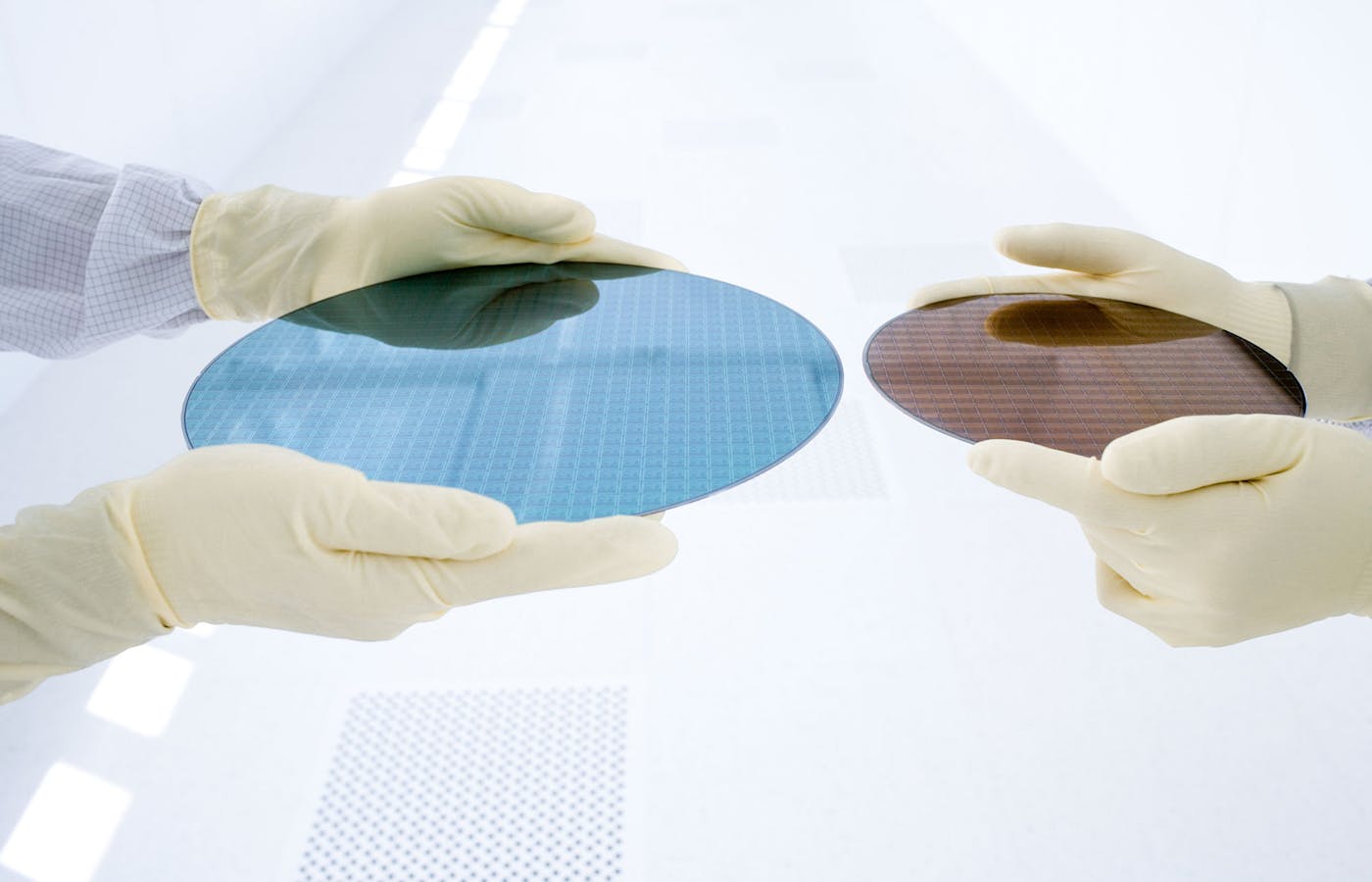

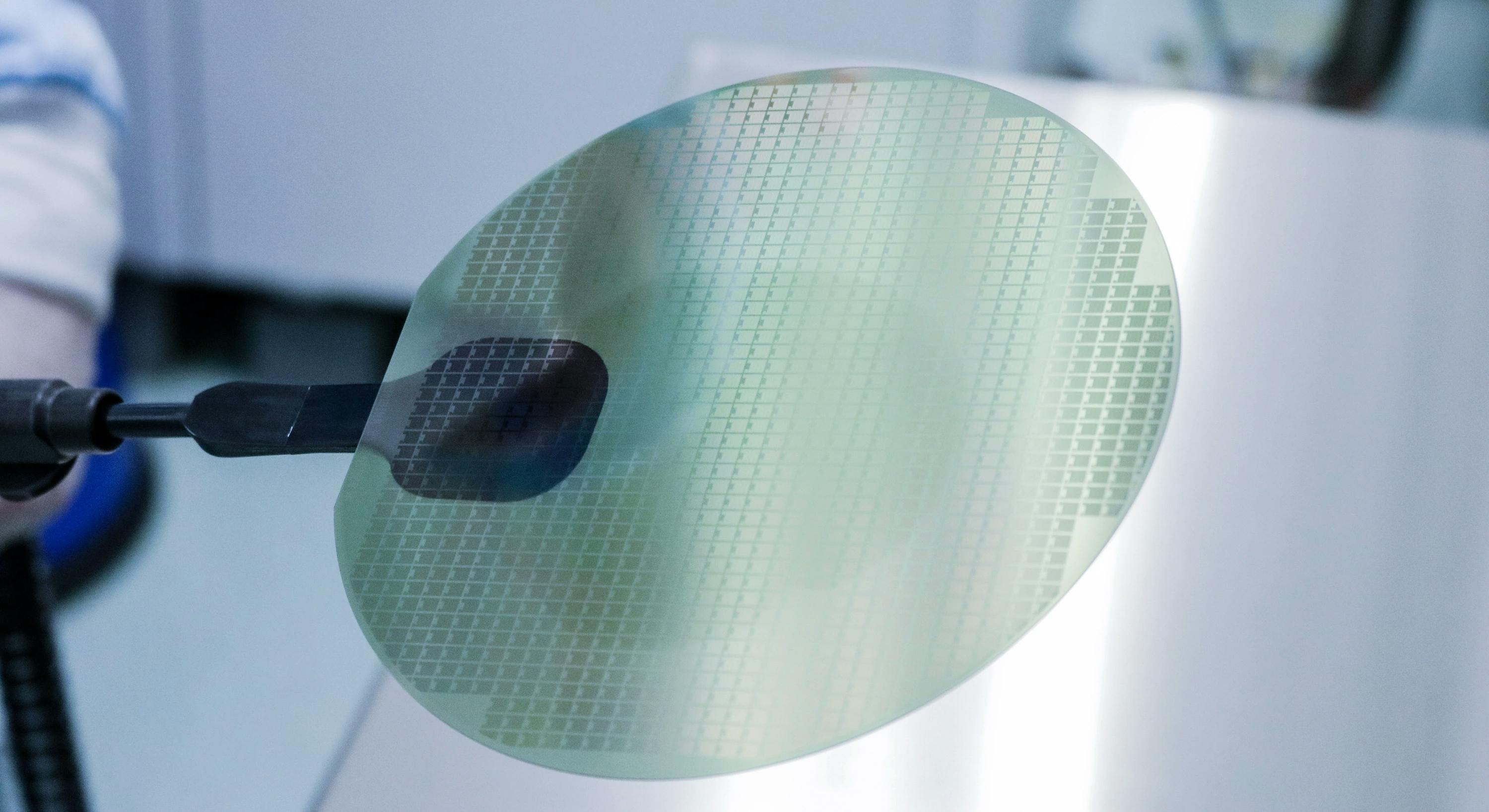

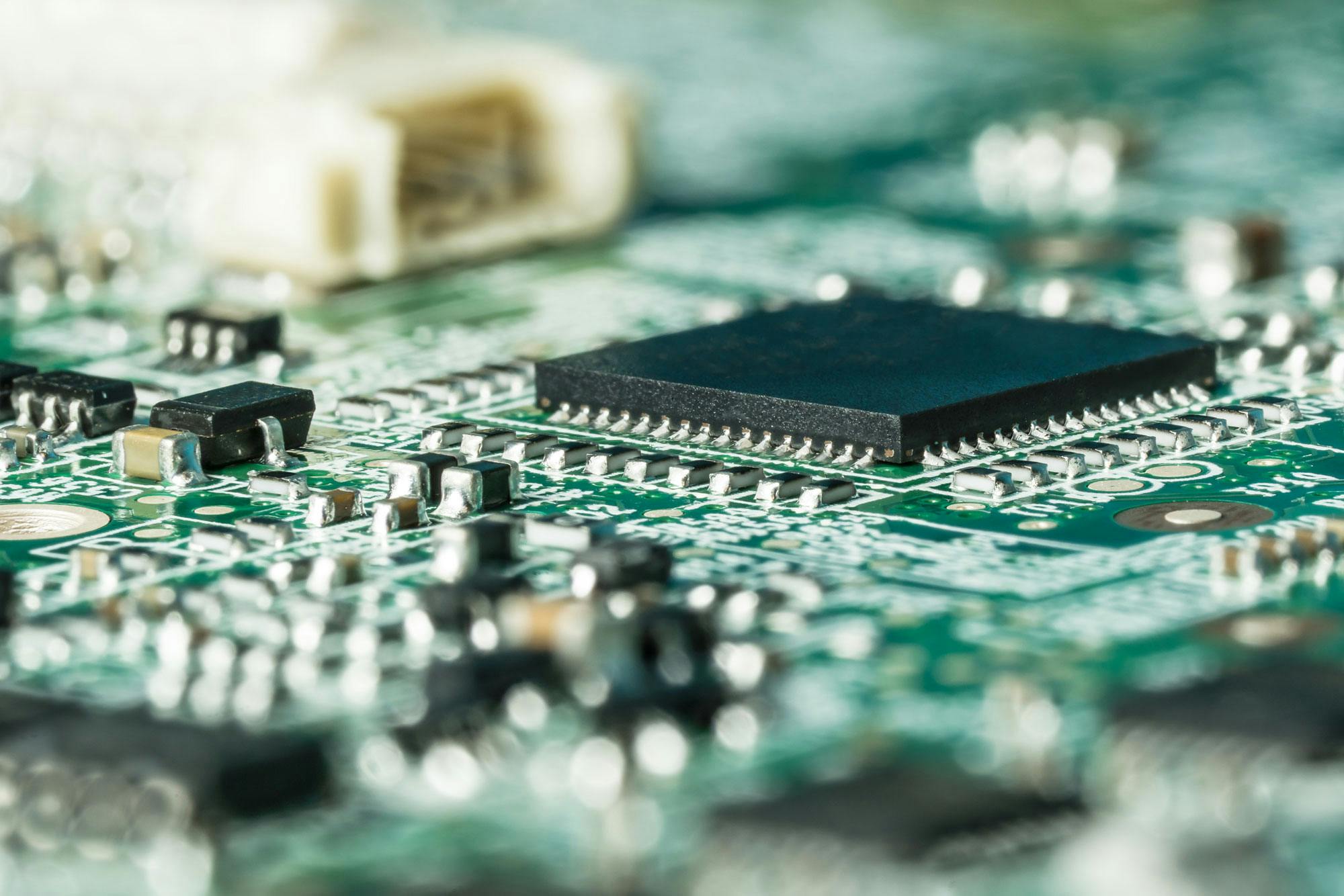

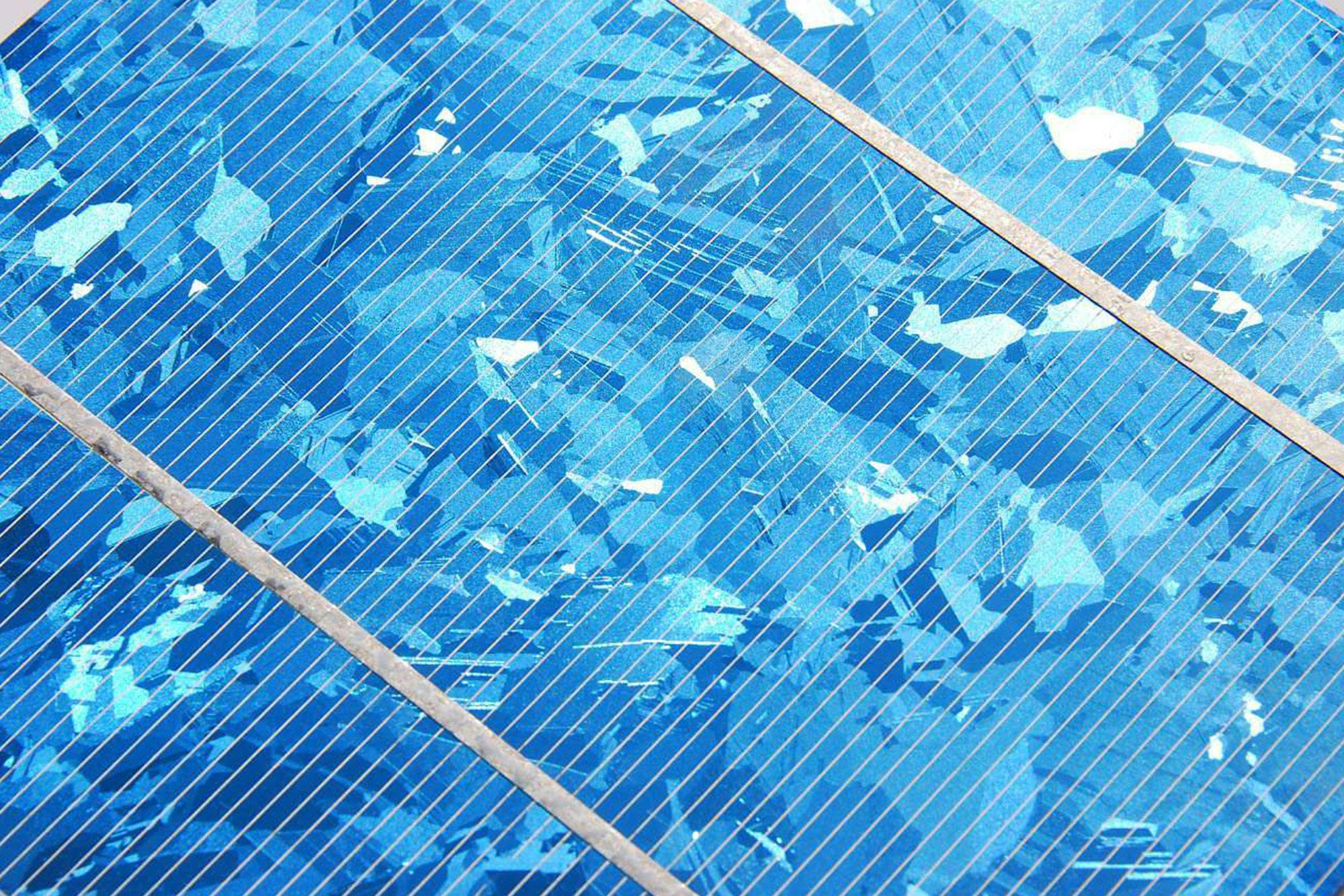

Thermal production solutions and coating technologies are among centrotherm's core competencies. For more than 70 years we have been developing and implementing production concepts for a constantly growing international customer base. In addition to growth sectors such as the semiconductor and microelectronics industry, as well as photovoltaics, our innovative solutions are also being applied in new future-oriented fields such as fiber or battery production.

As a leading, globally active technology group, we work closely with partners from industry and research. We improve existing production concepts and set new trends. In this way, we generate valuable competitive advantages for our customers. More than 650 employees worldwide are working to shape the future - GREEN | SMART | EFFICIENT.

Facts and figures

centrotherm worldwide

Click here to open the Cookie settings.

centrotherm international AG

Wuerttemberger Str. 31

89143 Blaubeuren

centrotherm international AG

Manfred-von-Ardenne-Ring 20

01099 Dresden

centrotherm international AG

Vahrenwalder Str. 269A

30179 Hannover

centrotherm Technology Shanghai Co. Ltd.

Room 803, Building B3

No. 180 Yizhou Road

Xuhui District

200233 Shanghai

centrotherm Machinery (Kunshan) Co. Ltd.

No. 665, Jiande Road

Zhangpu Town

215321 Kunshan

Jiangsu Province

centrotherm Asia Pte. Ltd. Taiwan Branch

13F-2, No 8, Ziqiang S Rd.

Zhubei City

Hsinchu County

30264, Taiwan

centrotherm Korea Ltd.

102-812,Digital-Empire II Bldg.

88, Sinwon-ro, Yeongtong-gu, Suwon-si,

Gyeonggi-do, 16681

centrotherm India Pte. Ltd.

No. 3, 2nd Floor A.V.S. Compound

80 feet Peripheral Road, 4th Block, Koramangala

Bangalore 560034, Karnataka

centrotherm Asia Pte. Ltd.

Blk 18 Sin Ming Lane #02-11

Midview City

Singapore 573960

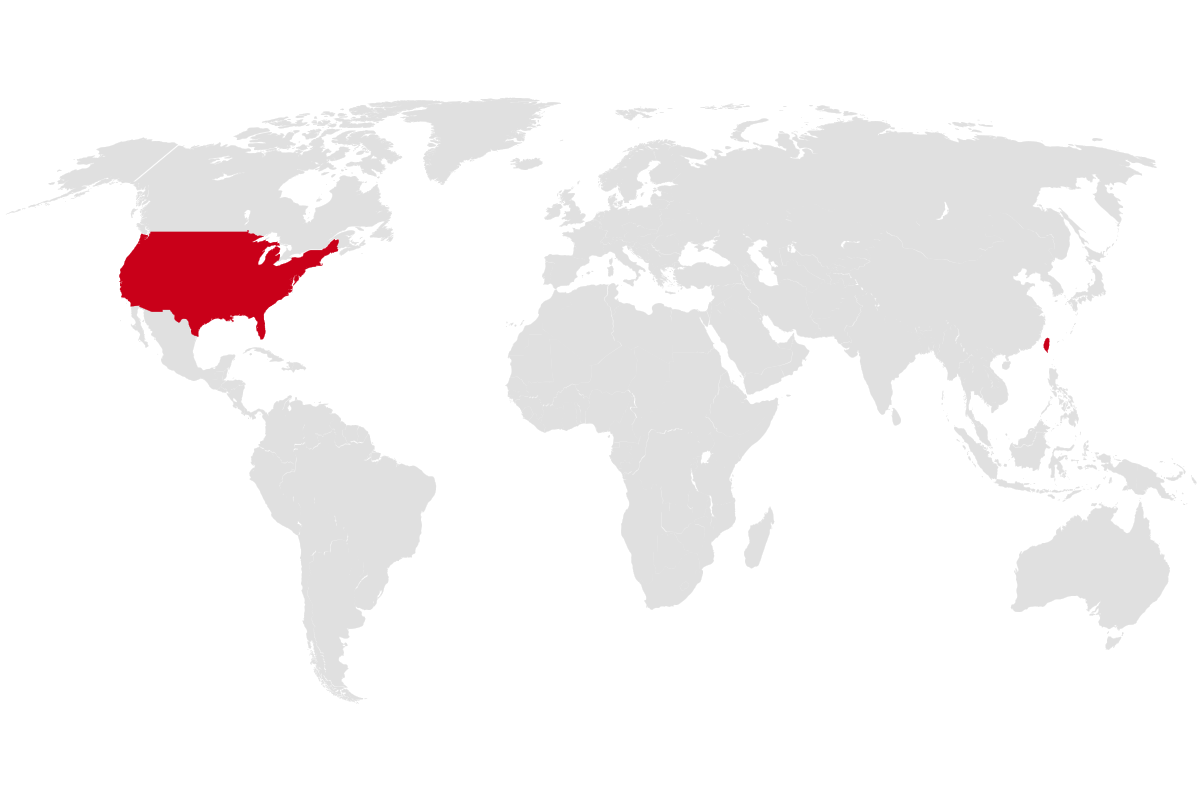

centrotherm USA Inc.

3333 Durham-Chapel Hill Blvd.

Suite D-200

Durham, NC 27707

EII Semiconductor Technologies Co.,Ltd

Room 812.Eternal Asia Plaza, No.202 Jinyue Rd

Pudong New Area

Shanghai 201206

Unisource Semiconductor Technologies, Ltd.

RM426, Dongmin building

Minkang Rd

Baoan

Shenzhen 518131

Hakuto Co. Ltd.

1-13, Shinjuku 1-chome, Shinjuku-ku

Tokyo 160-8910

Japan

IPT Corp.

#455-456, Incheon Industry Academy Collaboration Institute

Gaetbeol-ro 36, Yeonsu-gu,

Incheon, 21999

PTS - Puces Technologies Semiconducteurs

23 Rue Paul Héroult

38190 Villard Bonnot

France

TEC Associates Inc.

111 Deerwood Suite #198

San Ramon CA, 94583

USA

Board Members

Jan von Schuckmann | CEO

Jan von Schuckmann has been a member of the Management Board since May 2016, and CEO of centrotherm international AG since October 1, 2016. In addition to his activities as Chairman, he is responsible for the departments Production & Logistics, Purchasing, Finance, Service, Human Resources, Legal and Marketing.

Jan von Schuckmann was born in Darmstadt, Germany in 1968. He studied economics and has over 20 years of management experience. He initially held various management positions from 2002 to 2011, including CEO at office supplies company Herlitz AG. As a member of the Management Board from 2012 to 2014, he played a key role in the restructuring of centrotherm photovoltaics AG, and together with his former Management Board colleagues realigned the Group and successfully led centrotherm out of insolvency proceedings in self-administration at the beginning of 2013.

Dr. Helge Haverkamp | CTO

As Chief Technology Officer Dr. Helge Haverkamp has been responsible for centrotherm international AG's Technology, R&D, IT, and Quality Management divisions since September 1, 2021. He joined the company in 2019 as Head of Process Technology.

Dr. Helge Haverkamp was born in Salzgitter, Germany in 1974. After graduating in physics from the University of Heidelberg, Germany in 2003, he worked as research assistant in the industrial solar cell research group at the University of Constance, and as independent consultant for companies in the solar industry. In 2009, he completed his doctoral studies on the development of novel manufacturing processes for photovoltaics and moved to industry. While working, he completed an MBA distance learning program from 2015 to 2018. At the Schmid Group, a medium-sized company in the mechanical engineering and automation sector, he was initially a senior development engineer before taking over responsibility for Research & Development in 2014.

Supervisory Board

Board members

Dr. Helmut Gassel

Chairman

Stefan Kappis

Deputy Chairman

Robert M. Hartung

Board Member

Responsibility and quality

We are ISO 9001 certified

Our claim is to maintain our high quality standard

and to improve it continuously.

We are ISO 14001 certified

We are permanently concerned with environmental and climate protection

and work permanently on our environmental performance.

From pioneer to technology leader

The founding Hartung family exemplified a tireless pioneering spirit and tinkering with production solutions. Both characteristics are the cornerstones of our success. Our roots are in the semiconductor industry and over the past decades we have applied our knowledge to new growth industries. Discover our history and milestones of technological progress.

50 years of centrotherm

The centrotherm brand celebrates its 50th anniversary.

Ardian Semiconductor becomes majority shareholder

Ardian Semiconductor, a fund specializing in investments in the European semiconductor industry, acquires 90 percent of Solarpark Blautal's stake in centrotherm.

R&D center in Yiwu, China

Foundation of centrotherm Solar technology (Yiwu) Co. Ltd. for cooperative research and development of high-efficiency solar cell concepts with customers and partners.

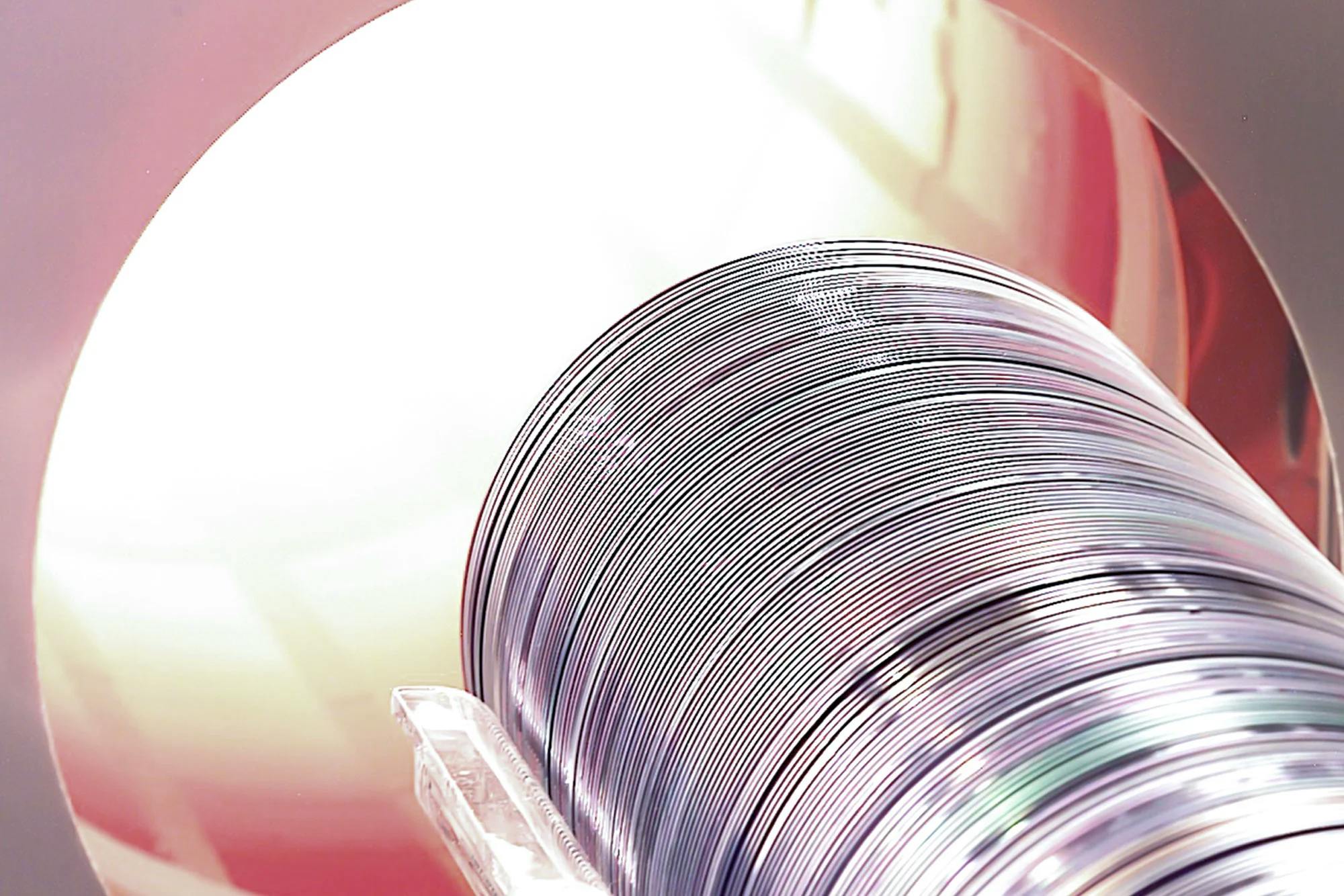

Upscaling of wafer sizes

centrotherm offers process technology for solar cells up to 210 mm diameter.

For the processing of silicon carbide, centrotherm supplies high-temperature furnaces for wafer sizes up to 200 mm to Europe's first pilot line for the production of next-generation power electronics as part of the EU-funded REACTION project.

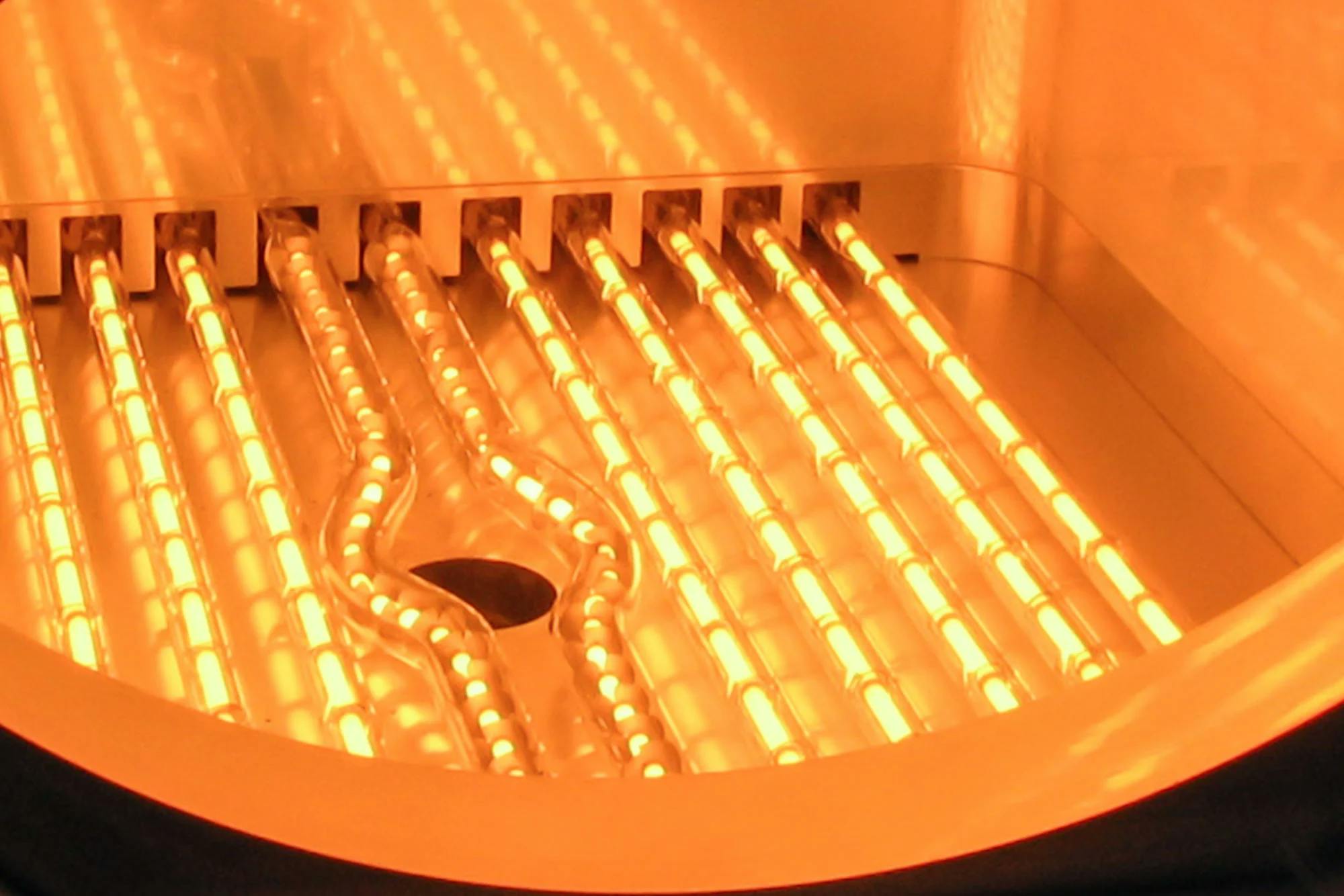

1250 °C high-temperature process

The first horizontal system with high-temperature capability up to 1250 °C is introduced.

System generation X

With our new 10-tube process systems for diffusion and PECVD our customers achieve a significant increase in their production capacity.

Production site Kunshan

With centrotherm Machinery (Kunshan) Co. Ltd. founded in 2018, centrotherm has expanded its production capacity and is able to act faster and more flexibly on the important Chinese market.

Solar energy cheaper than fossil power in Germany

According to Fraunhofer ISE, PV’s Levelized Cost of Energy (LCOE) ranges between €0.0371 and €0.1154 per kWh in Germany. This makes newly constructed PV systems cheaper than fossil power plants for the first time.

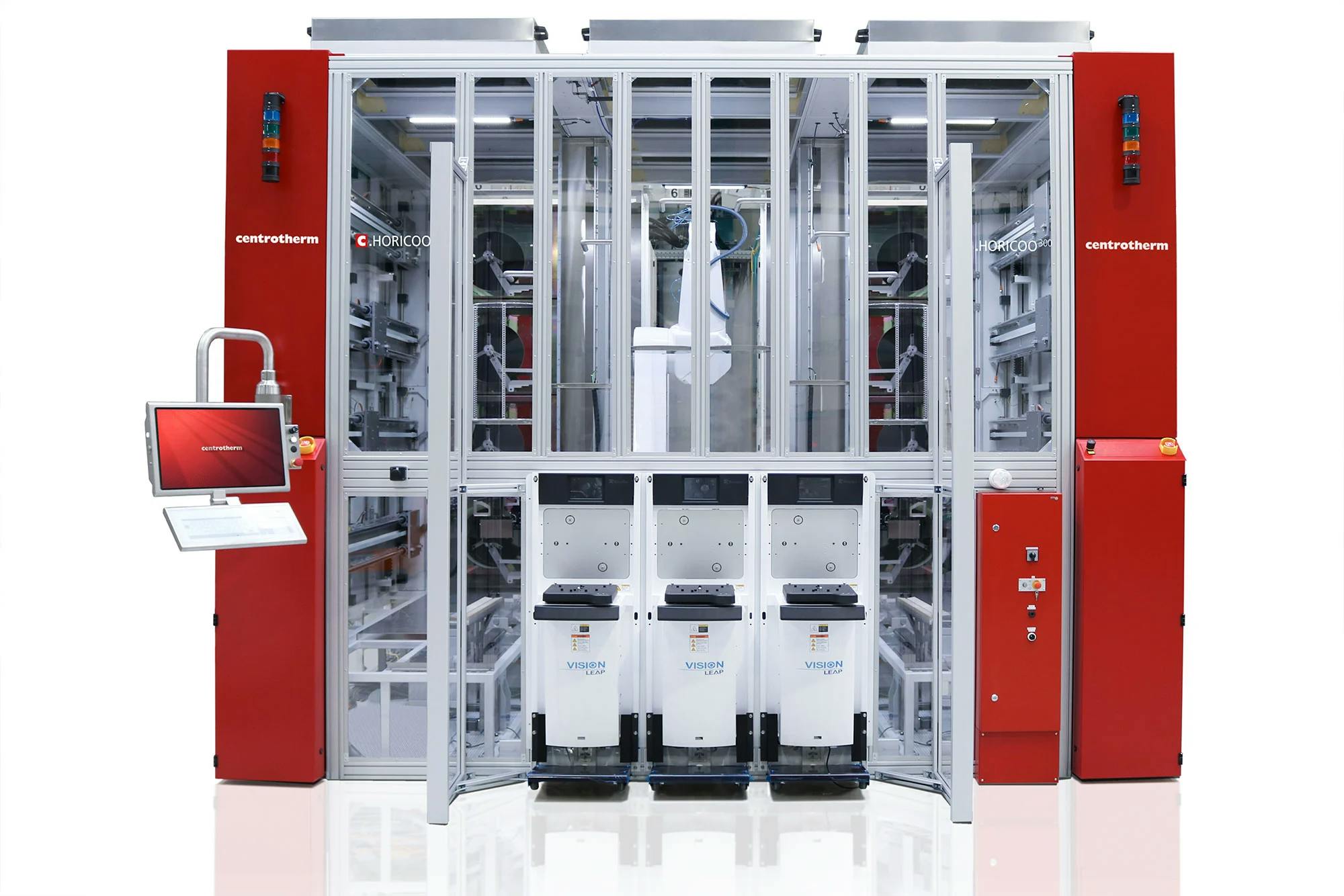

Launch of c.HORICOO 300

With the c.HORICOO 300 centrotherm launches a horizontal furnace cluster with 8 process tubes for highly efficient mass production of 300 mm wafers.

centrotherm international AG

New company name: centrotherm international AG

Process technology for PERC solar cells

With the triumphant success of PERC solar cells, we rise to become technology leader and industry standard for PECVD-AlOx coating.

India branch

Foundation of a sales and service branch in Bangalore

First SiC Power MOSFET

CREE Inc. introduces the first fully qualified commercial silicon carbide power MOSFET for energy-efficient power electronics. This new benchmark for power switches makes it possible to develop high-voltage circuits with very fast switching speeds and ultralow losses.

China and Korea branches

Foundation of sales and service branches in China and Korea

Taiwan and USA branches

Foundation of sales and service branches in USA and Taiwan

IPO

IPO of centrotherm photovoltaics AG

Singapore Branch

Foundation of centrotherm photovoltaics Asia Pte. Ltd. in Singapore

Turnkey solar cell production lines

By expanding its portfolio to include turnkey production lines, centrotherm becomes the most important initial equipment supplier for Asian cell manufacturers, and rises to become the global market leader in this business field.

centrotherm photovoltaics

Foundation of centrotherm photovoltaics AG

High-temperature SiC processing

centrotherm introduces high-temperature equipment for silicon carbide (SiC) processing. Due to their large band gap SiC switches operate stably in electrical applications up to 600 °C what makes SiC especially relevant for power electronics. Under harsh thermal conditions, SiC operates reliably and permanently and provides 10 times the mean time to failure (MTTF) compared to silicon.

Expansion of PV business

centrotherm expands its solar business with first joint research projects with the Fraunhofer Institute and enters the Asian market.

First vacuum soldering systems

centrotherm presents first vacuum soldering systems.

Invention of PERC solar cell

The PERC solar cell design was developed at the University of New South Wales. It took another three decades for PERC technology to account for at least half of the world solar cell manufacturing capacity.

First RTP system

centrotherm launches first rapid thermal processing equipment

First reflow soldering furnace

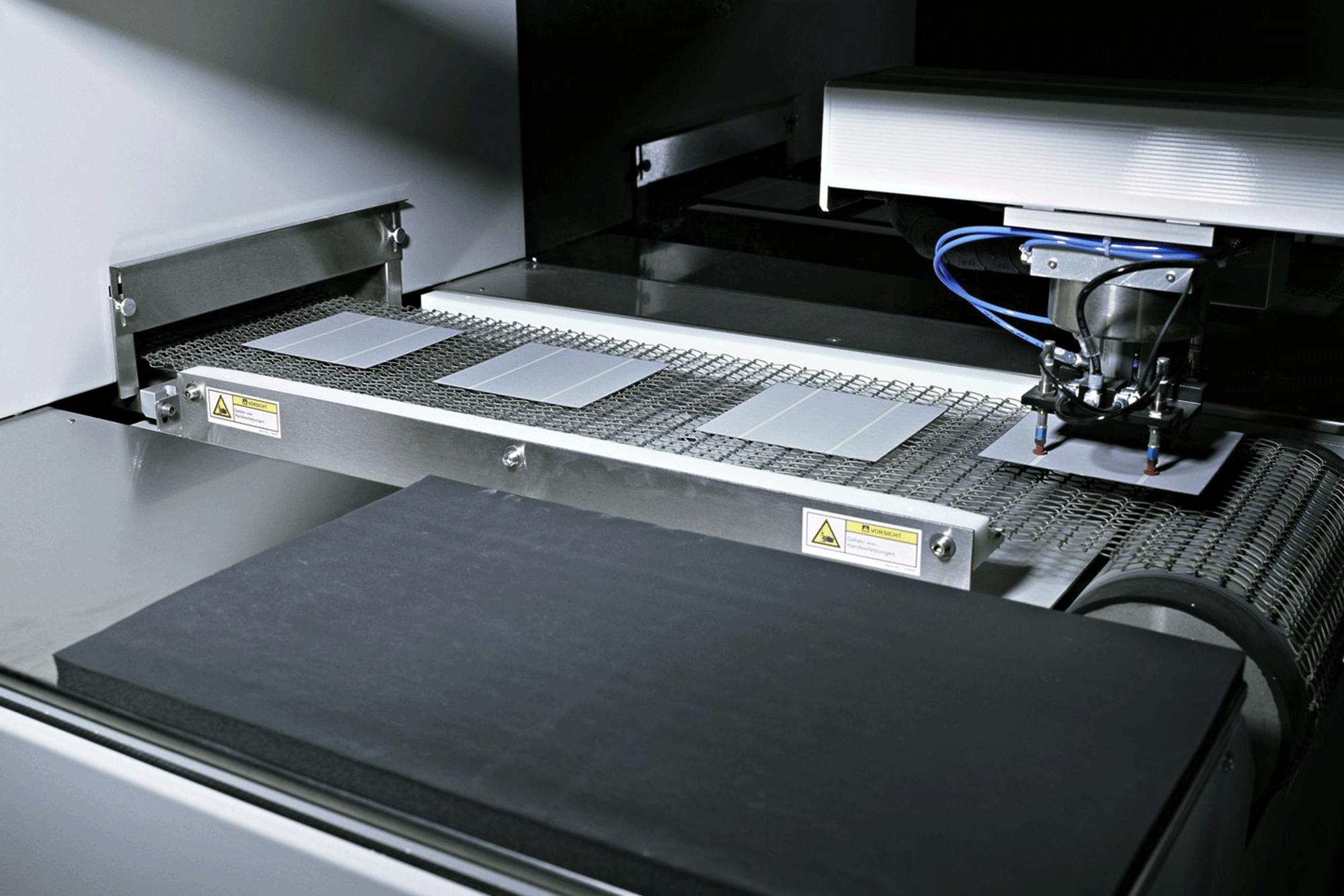

centrotherm launches the first conveyor furnace for reflow soldering which is todays most common technology for SMD components.

Entry into PV market

centrotherm enters the solar market and delivers the first products to the photovoltaics industry.

Foundation of centrotherm Elektrische Anlagen GmbH

centrotherm Elektrische Anlagen GmbH is founded.

First mobile phone

The advancements of MOS, large-scale integration technology, information theory and cellular networking led to the development of mobile communications. The first handheld mobile phone was demonstrated by Motorola using a handset weighing approximately 2 kg.

Start of automation

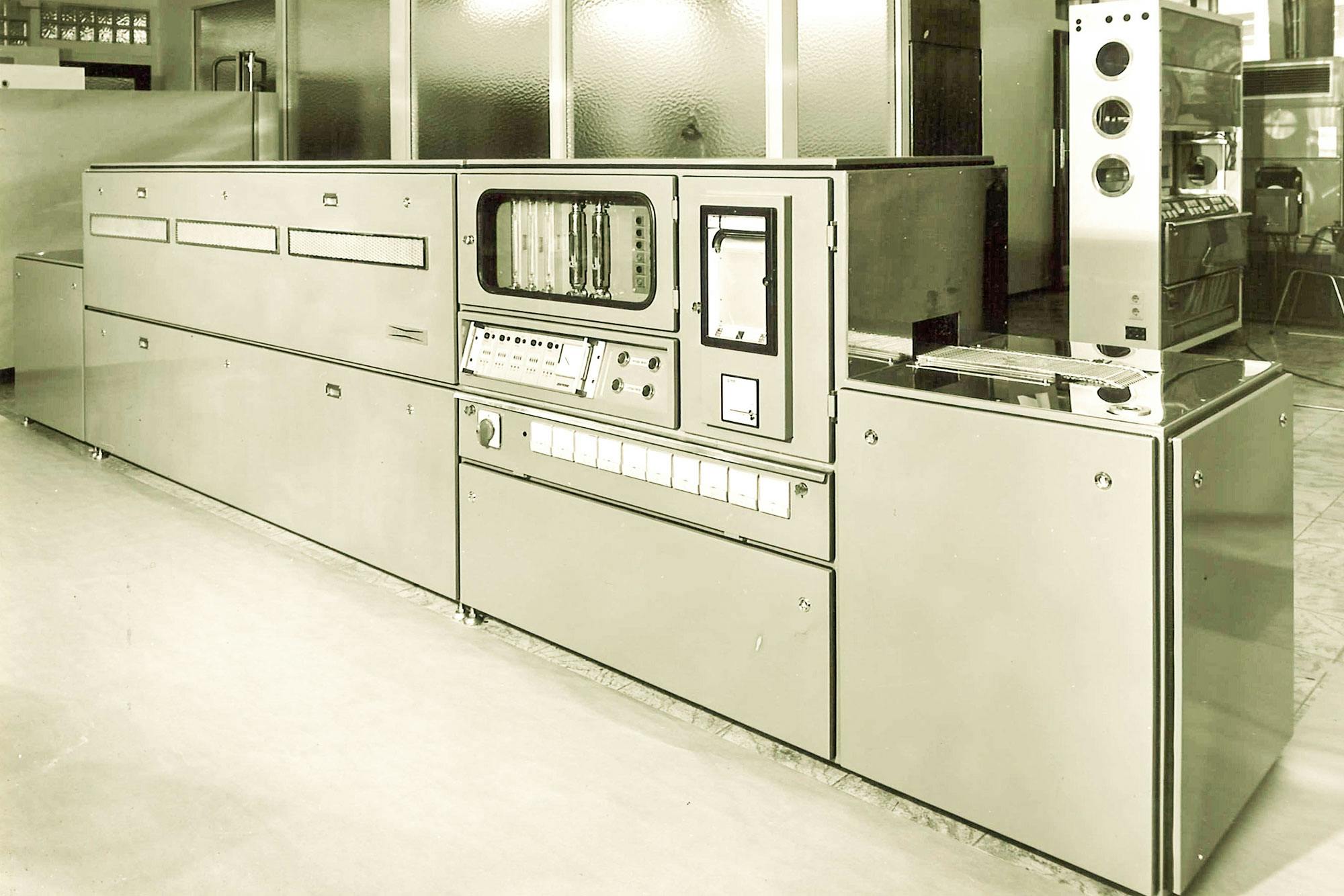

The first equipment with automated loading system is introduced.

Moore's law and the first MEMS devices

With his brief article entitled "Cramming more components onto integrated circuits", Gordon Moore predicts the future of the semiconductor industry over the following ten years. It says that the number of transistors in a dense integrated circuit doubles about every two years. Moore's prediction has been used in the semiconductor industry to guide long-term planning and to set R&D targets.

Harvey C. Nathanson invents the first Micro-Electro-Mechanical System of the type that is nowadays found in smartphones and vehicles. MEMS devices, composed of small moving mechanical elements that generally range from 1 to 100 micrometers in size, were developed for measuring physical, chemical, biological and environmental parameters.

Mass production of solar cells

Sharp begins to successfully mass-produce solar cells, which brings solar practicality down from space shuttles and satellites to the general public.

First vertical furnace

The company's first vertical tube furnace is launched

First conveyor furnace

The company launches its first conveyor furnace for the electronics industry

MOS transistor

Mohamed Atalla and Dawon Kahng successfully fabricate the first working MOSFET device. The advantage compared to planar junction transistors is that it is more compact and more suitable for mass production.

World's first silicon solar cell

Bell Labs announces the invention of the first silicon based solar cells with about 6% conversion efficiency. The New York Times headlines that solar cells will eventually lead to a source of "limitless energy of the sun."

First diffusion furnace

The first diffusion furnace is developed in Blaubeuren.

Foundation of K.C. Hartung Apparatebau

K.C. Hartung Apparatebau is founded by Karl Christian Hartung. The original company of centrotherm starts with special plant engineering for thermal processes.

First transistor

Bell Labs demonstrates a germanium point-contact transistor. William Shockley, John Bardeen and Walter Brattain are credited with this invention and share the 1956 Nobel Prize in Physics for their achievement.