MEMS technology

When the display of your smartphone turns on as soon as you look at it or when the screen rotates to the orientation in which it is held. When your car stabilizes itself after skidding. Or when your airbag deploys at just the right moment. Then you can be sure that microelectromechanical systems, or MEMS for short, are at work.

MEMS could also be described as the sensory organs of many products and applications. It is impossible to imagine the automotive, industrial, aerospace, medical and consumer electronics sectors without them. Especially in the automotive sector, the demand for MEMS is increasing rapidly due to increasing electrification and autonomous driving. However, MEMS are also on the rise in the manufacturing industry and consumer electronics in connection with Industry 4.0 and IoT.

What makes a MEMS device?

MEMS are tiny devices that combine electronic logic elements and micromechanical structures in one chip.

Micromechanical elements

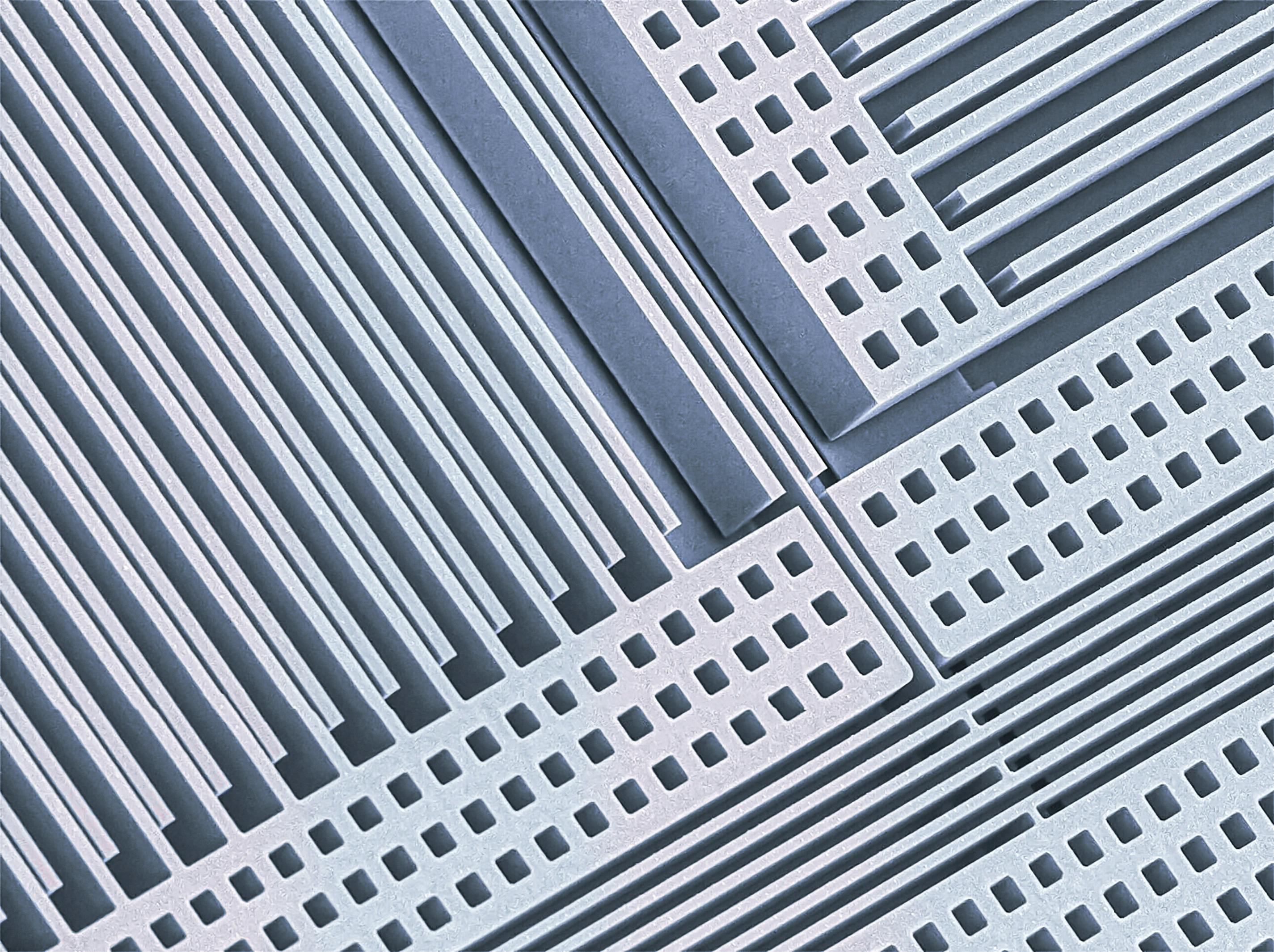

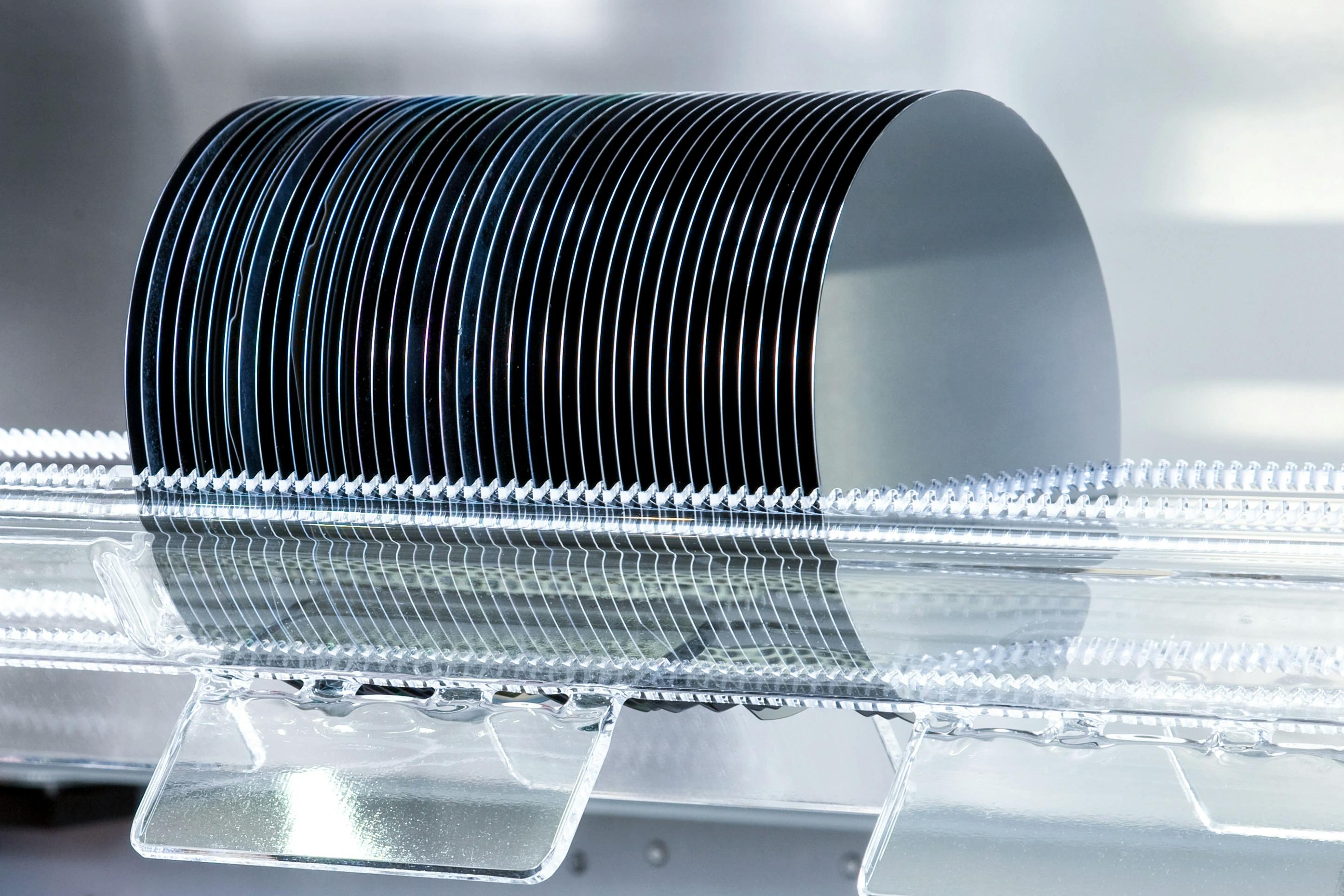

The micromechanical elements are usually made of silicon. Depending on the application, movable 3D comb structures or membranes, for example, are etched onto the wafer surface, some of which have a dimensional spectrum of well below one micrometer and are thus far thinner than a human hair. They measure minimal external influences such as pressure, movement, light or even gas. If the combs move against each other in acceleration sensors, the electrical charge between the combs changes.

Electronic elements

The electronic circuit (ASIC) receives the signal of an environmental change, converts it into a digital value and passes it on to the controller or microcontroller of the device or, for example, the car. Silicon is also used as the base material, on which integrated circuits are applied as the result of many different process steps.

The micromechanical and electronic elements are produced separately. In a further production step, they are connected to each other and encapsulated to the finished chip.

How does centrotherm process technology contribute?

For MEMS manufacturing, centrotherm offers LPCVD, atmospheric annealing and oxidation processes for wafer processing, the so-called front-end-of-line (FEOL) processes. For encapsulation of the finished chips, we provide vacuum soldering systems for hermetic sealing.