Alternative carbon fibers

The extreme tensile strength and stiffness combined with low density make carbon fiber composites ideally suited for components that are subjected to heavy loads and extreme temperatures and have to be very light.

Due to their high cost, however the use of carbon fibers has so far been largely limited to high-end applications such as aerospace or Formula 1 and high-priced end products. The established production process is time-consuming and cost-intensive. Firstly, precursor fibers (precursors) - mostly made of polyacrylonitrile (PAN) - have to be produced in a complex process using toxic solvents. The biggest cost factor is the energy-intensive thermal processing, where waste gases must be carefully separated and purified.

New fields of application lead us to expect an enormous increase in demand in the coming years: carbon fibers are predestined for use in electric vehicles or wind turbines. On the other hand, fiber-reinforced concrete is moving into the focus of the construction industry as a replacement for corrosion-prone reinforced concrete. The increasing demand calls for more cost-effective and faster manufacturing processes with lower energy consumption as well as sustainable and environmentally friendly precursor materials.

What’s behind alternative carbon fibers?

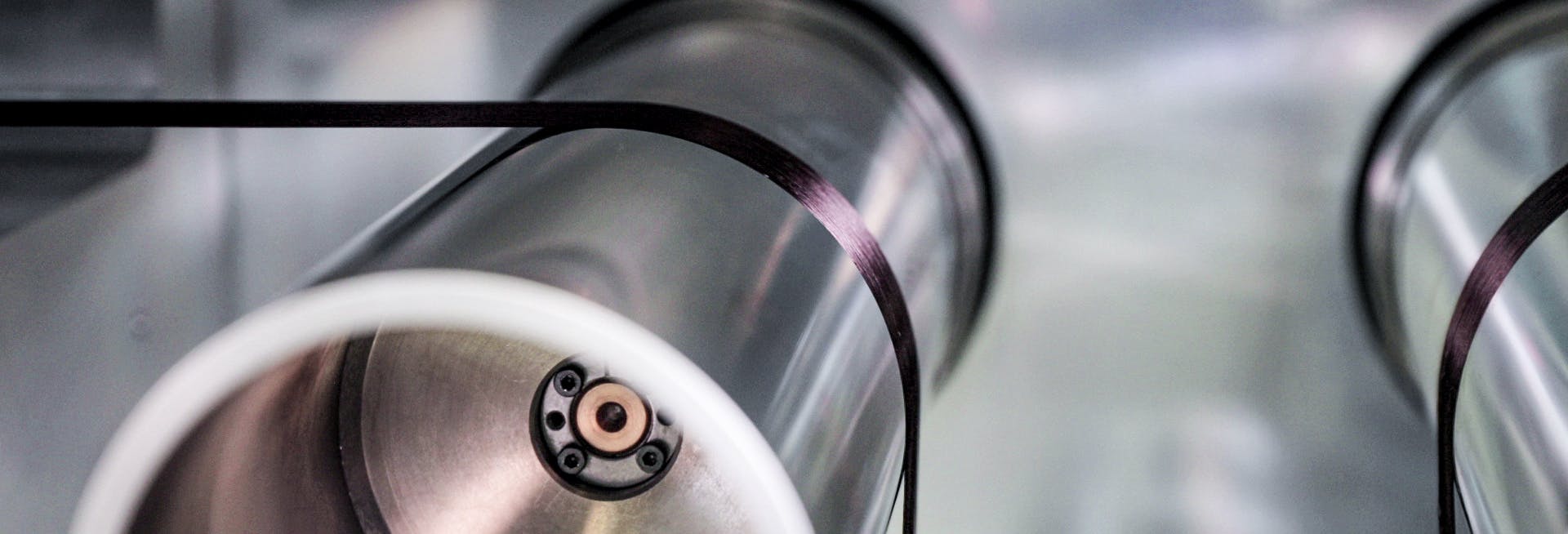

Carbon fibers are characterized by a high carbon content of more than 90% and, with a diameter of 5-10 micrometers, are around 10 times thinner than a human hair. Several thousand carbon fiber filaments are bundled into a tow that can be used individually or woven into a fabric.

Due to the high price and dependence on fossil raw materials, renewable and cost-effective alternatives for PAN precursors are coming into the focus of manufacturers.

Carbon fibers from renewable raw materials

As components of plant cell walls, the macromolecules lignin and cellulose are the most frequently occuring organic substances on earth and a very good alternative to PAN.

Lignin is a by-product from the paper industry and consists of 60 percent carbon atoms. It has a similar pre-structure to the finished carbon fiber.

Cellulose accounts for 40-50 percent of the basic structure of trees and gives them the stability to withstand enormous tensile forces.

The side reactions of current manufacturing processes impair the carbon yield of bio-based precursors and lead to a high material loss. At most, one third of the precursor is converted into a carbon fiber.

Homo-PAN carbon fibers

A large cost saving is possible with the use of homo-PAN precursors, which are 35-40% cheaper to produce than PAN precursor fibers. Due to fewer refinement steps, homo-PAN precursors do not have a copolymer structure, which simplifies subsequent stabilization of PAN. The more sensitive Homo-PAN therefore requires a much smaller process window.

How does centrotherm process technology contribute?

centrotherm provides the key thermal processes for the production of carbon fibers. These include oxidative stabilization of precursor fibers, low-temperature carbonization, and an ultra-high temperature process for graphitization.

Our innovative low-pressure oxidation revolutionizes fiber production with significant cost advantages - especially for cellulose as well as for PAN and homo-PAN fibers.