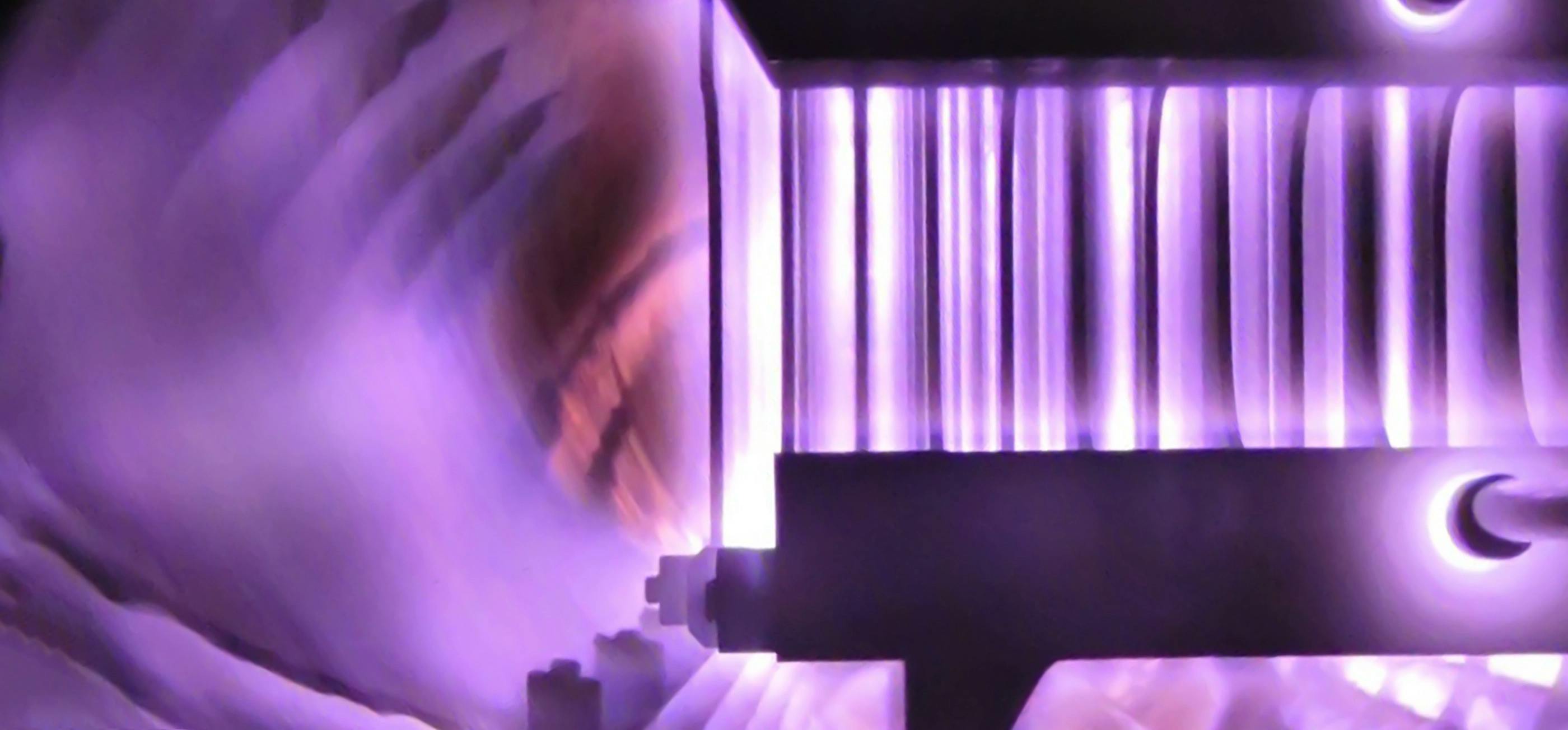

With more than 1250 units installed worldwide, the centrotherm PECVD platform c.PLASMA is the leading technology and industry standard for solar cell passivation and anti-reflective coating. The system uniquely combines high throughput, outstanding process performance and lowest total cost of ownership. It ensures smooth operation in case of varying production loads and process sequences.

centrotherm provides two main configurations differing in wafer size, capacity and throughput.

In addition to the 5-chamber version for wafers up to 166 mm centrotherm introduced the next level c.PLASMA X that pushes the boarders for the PV industry. Based on the well-proven platform, it sets new standards for highest throughput. The 10-tube design provides the same maximum flexibility and system availability for wafer sizes up to 210 mm. On top, it delivers remarkable footprint savings with its integrated TMA supply and vacuum pumps.

Processes

PECVD processes

- Silicon Nitride (SiNx)

- Aluminum Oxide (AlOx)

- Silicon Oxide (SiOx)

- Silicon Oxynitride (SiONx)

- Polysilicon

Further processes

- Multi-layer stacks

- Graded layers

Features & Benefits

Industry-leading passivation layers for PERC solar cells

- AlOx/SiNx stack deposition with outstanding passivation properties at thicknesses from 4 - 10 nm

- AlOx/SiNx stack is deposited in one run by just switching process gases

- Easy stack modification by recipe change

Best-in-class anti-reflective coating with maximum process flexibility

- Excellent hydrogen passivation from SiNx layers

- Graded and multiple layers for improved AR coating in a wide wavelength range

- Improved efficiency and cell appearance

- Outstanding conformal surface coverage

- Applicable in Cz and mc-Si solar cell production