Silicon carbide solutions form the focus of centrotherm's appearance at the SEMICON Europa trade fair in Munich

- Development of a new generation of systems for 200 mm silicon carbide wafers

- centrotherm as project partner in the European REACTION research project

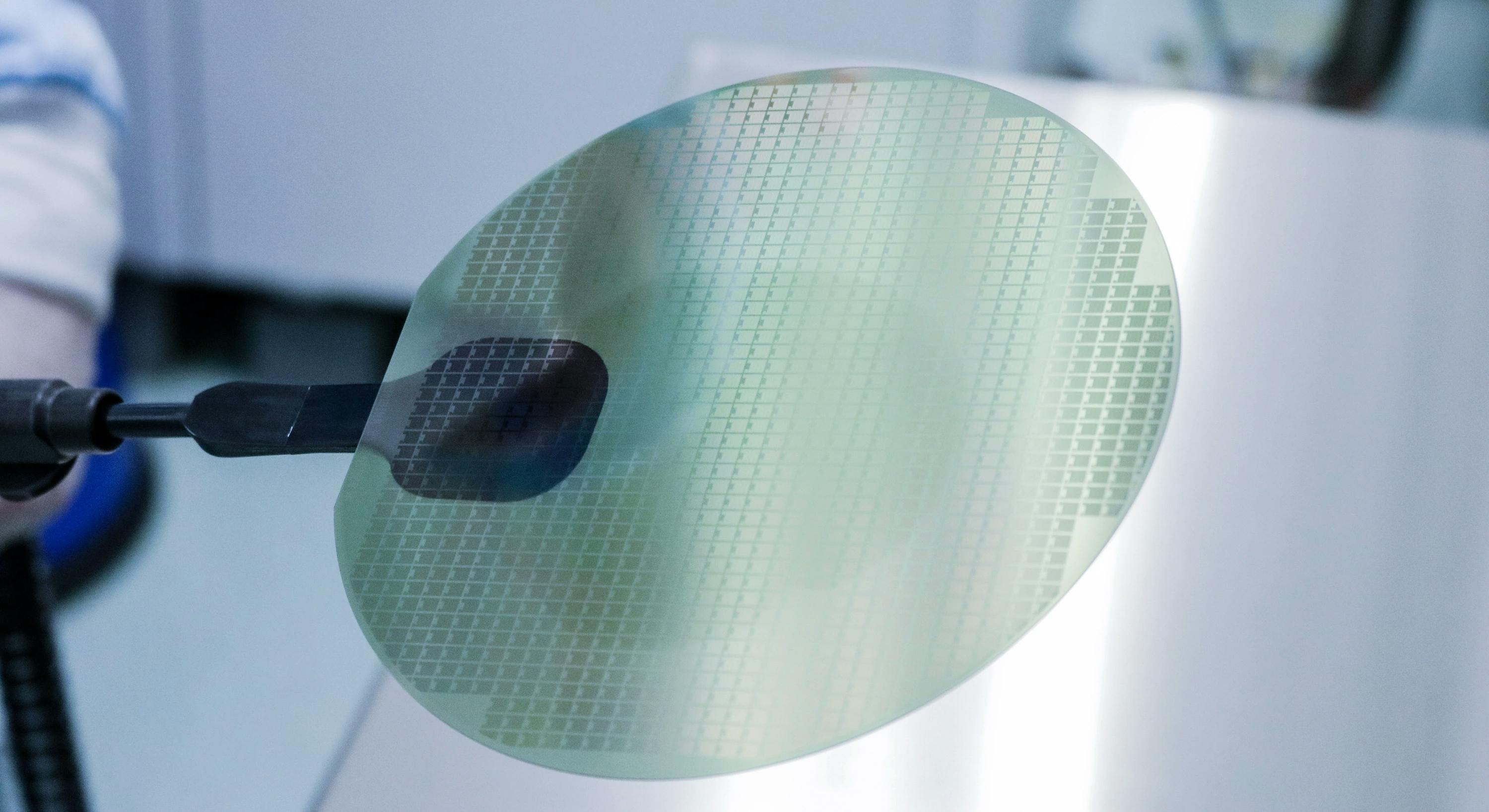

centrotherm international AG, Blaubeuren, (ISIN: DE000A1TNMM9 and DE000A1TNMN7) has the future in its sights with its new system generation for 200 mm silicon carbide wafer processing. Demand for high-performance electronics such as transistors and diodes is rising rapidly in tandem with advancing digitalization, e-mobility and renewable energy generation. The conversion of high electrical power usually also requires components offering greater dielectric strength. For such applications, silicon carbide (SiC) semiconductor devices offer better efficiency, higher temperature stability and reliability in harsh environments.

Commanding an approximately 95 % share of the market, centrotherm is the leading supplier with its high-temperature furnaces for post-implantation annealing and hydrogen annealing of 150 mm SiC wafers. The company’s systems are in production at renowned manufacturers worldwide. With its new c.ACTIVATOR 200 and c.OXIDATOR 200 system generation, technology and system supplier centrotherm is now offering production solutions for larger wafers at temperatures of up to 2,000 C° and 1,500 C° respectively. The benefits for the semiconductor industry are clear: with 200mm SiC wafers, semiconductor manufacturers can reduce costs by up to 23 %, while enhancing product per-formance and safety. centrotherm systems' small footprint, high productivity and side-by-side installation contribute to further cost savings. Both system types are based on the same platform and can process wafer sizes of 150 mm and 200 mm as so-called bridge tools.

centrotherm is a project partner in the European REACTION research project for the construction of the first European 200 mm SiC production line in Catania, Italy. The c.ACTIVATOR 200 and c.OXIDATOR 200 high-temperature furnaces will be delivered to Catania in the coming year. The REACTION project is sponsored by the EU and the Federal Ministry of Education and Research in the framework of ECSEL (Electronic Components and Systems for European Leadership).

Visit us at SEMICON Europa from November 12-15 at Messe München, Booth B1/313.

About centrotherm international AG

Thermal production solutions and coating technologies are among centrotherm's core competencies. For more than 70 years we have been developing and implementing production concepts for a constantly growing international customer base. In addition to growth sectors such as the semiconductor and microelectronics industry, as well as photovoltaics, our innovative solutions are also being applied in new future-oriented fields such as fiber or battery production.

As a leading, globally active technology group, we work closely with partners from industry and research. We improve existing production concepts and set new trends. In this way, we generate valuable competitive advantages for our customers. More than 700 employees worldwide are working to shape the future - GREEN | SMART | EFFICIENT.

centrotherm international AG

Württemberger Str. 31

89143 Blaubeuren

Internet: www.centrotherm.de

German Securities Identification Number (WKN): A1TNMM (bearer shares); A1TNMN (unlisted shares from the non-cash capital increase)

ISIN: DE000A1TNMM9 (bearer shares); DE000A1TNMN7 (unlisted shares from the non-cash capital increase)

Inclusion: Basic Board, Frankfurt Stock Exchange

Corporate domicile: Germany